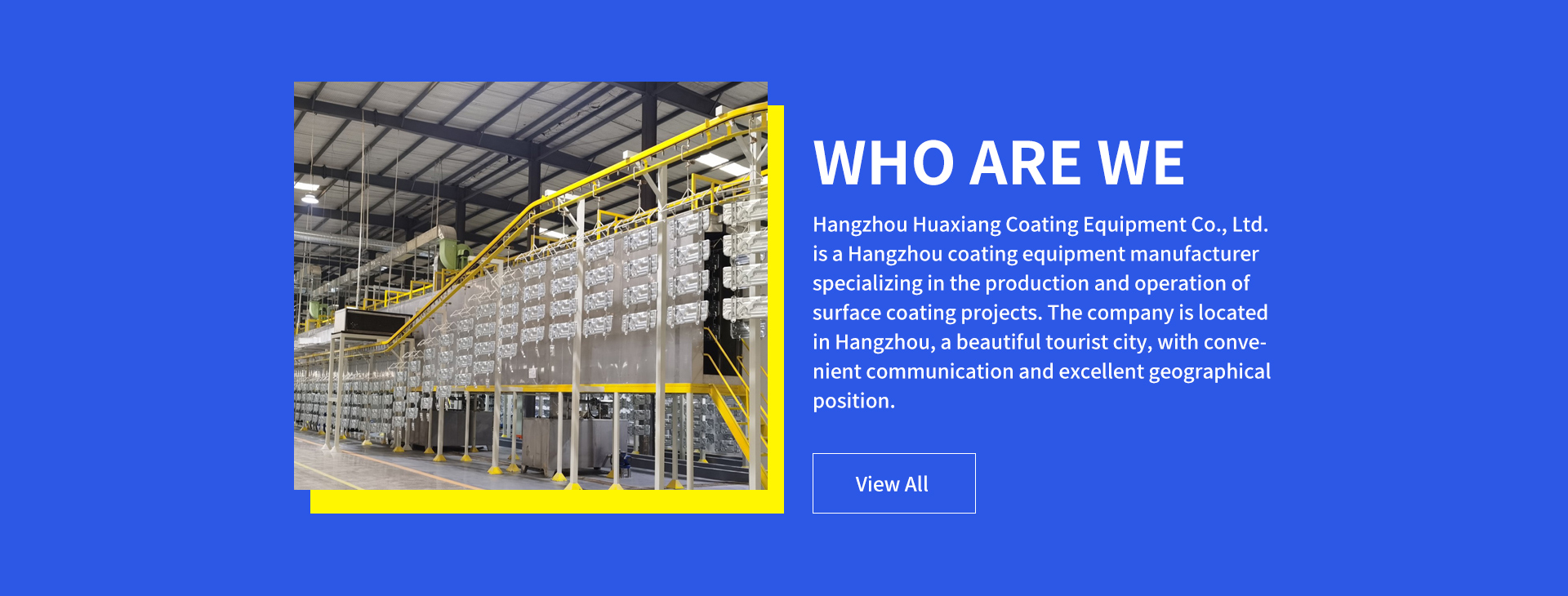

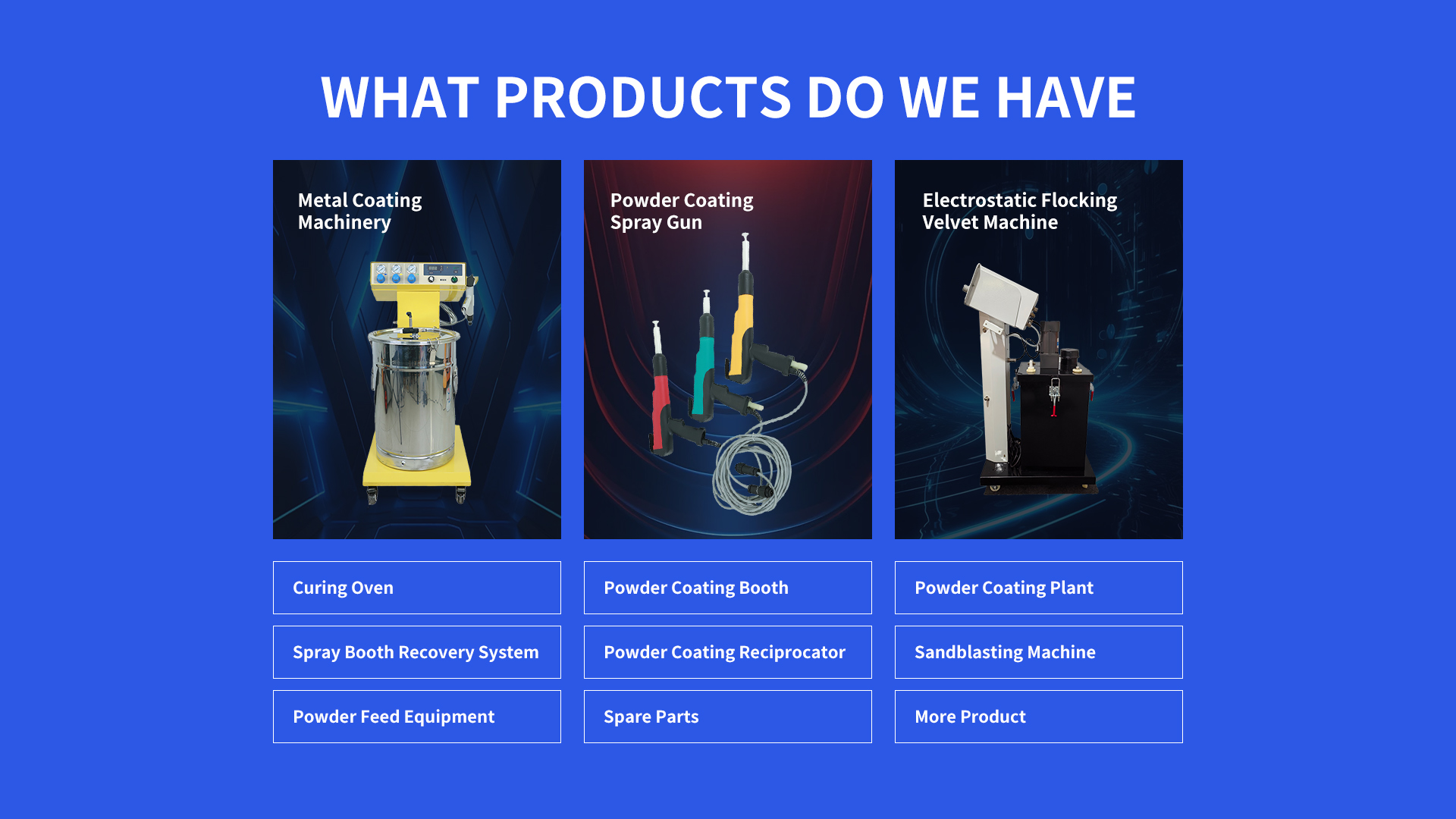

1. Powder Coating Equipment Factory Overview and Components

A Powder Coating Equipment Factory produces systems for applying and curing powder coatings. Key components include electrostatic spray guns, powder booths, curing ovens, conveyor systems, and recovery units. Advanced models feature IoT-enabled controls, robotic arms, and modular designs for scalability and precision.

2. Applications of Powder Coating Equipment Factory Systems

Widely used in automotive (wheels, chassis), aerospace (engine parts), appliance manufacturing (refrigerators, ovens), and architectural metalwork. These systems deliver uniform, corrosion-resistant finishes on metals, plastics (with primers), and composites, ideal for high-volume production.

3. Pricing of Powder Coating Equipment Factory Systems

Manual Systems: 10,000–50,000 (basic booths, small-scale production).

Semi-Automated Lines: 50,000–200,000 (robotic arms, medium throughput).

Fully Automated Lines: 200,000–1 million+ (IoT integration, 500+ parts/hour).

Energy-efficient designs with heat recovery reduce operational costs by 25–40%.

4. Proper Operation of Powder Coating Equipment

Pre-treat surfaces via sandblasting or chemical cleaning.

Adjust spray gun voltage (40–100 kV) and airflow (10–30 psi) for even coverage.

Cure parts at 300–450°F for 10–30 minutes.

Clean filters and nozzles daily to maintain efficiency.

5. How to Choose Equipment from a Powder Coating Equipment Factory

Production Volume: Manual systems suit <100 parts/day; automated lines handle 500+/hour.

Material Compatibility: Verify support for epoxy, polyester, or hybrid powders.

Certifications: Prioritize CE, UL, or OSHA compliance.

Customization: Opt for modular designs to expand conveyor length or add curing zones.

6. Safety Precautions for Powder Coating Equipment

Install explosion-proof ventilation to manage combustible dust.

Use NIOSH-approved respirators (N95+) and anti-static gear.

Ground all equipment to prevent electrostatic discharge.

Store powders in temperature-controlled, fire-resistant containers.

7. Cost-Efficiency of Powder Coating Equipment Factory Designs

Automated systems reduce labor costs by 50% and material waste by 90%. High-efficiency recovery systems reclaim 95%+ overspray, while energy-saving ovens cut power use by 30%. ROI is typically achieved within 2–3 years for high-volume production.

8. FAQs About Powder Coating Equipment Factory Systems

Q: What industries benefit most from powder coating equipment factories?

A: Automotive, aerospace, and appliance sectors rely on these systems for mass production.

Q: How to minimize powder waste in factory systems?

A: Use cyclone separators and HEPA filters for 95–99% recovery rates.

Q: Can powder coating equipment handle heat-sensitive materials?

A: Yes—UV-curable powders and low-temperature ovens protect plastics and wood.

Q: Are factory-made systems eco-friendly?

A: Yes—zero VOC emissions and 98% powder reuse align with sustainability goals.

Q: What certifications ensure safety?

A: Look for CE, UL, or ATEX compliance from the powder coating equipment factory.

This guide provides actionable insights into powder coating equipment factory solutions, helping businesses optimize efficiency, safety, and ROI in industrial finishing operations.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com